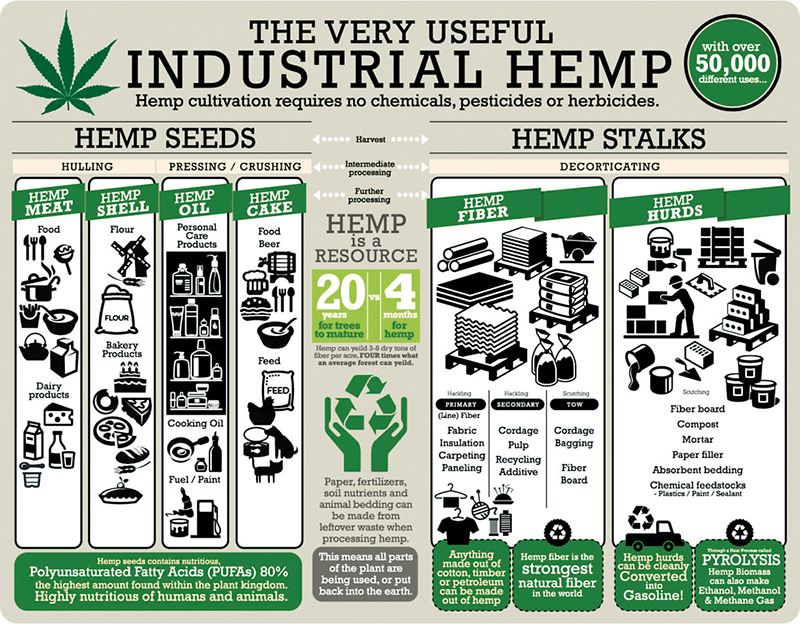

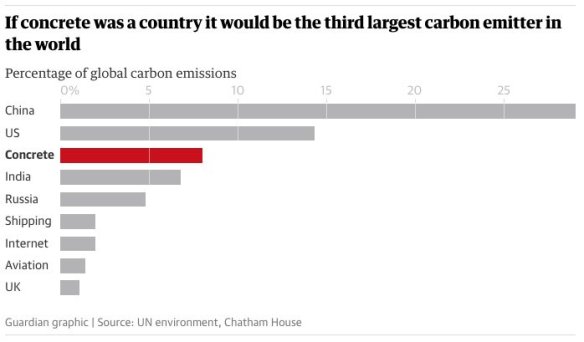

The making and use of cement concrete causes of an estimated 5% of global warming emissions. Hemp concrete made from hemp stalk is lighter and more porous and known to sequester carbon. Beautiful model homes have been made from hemp concrete and industrial hemp has finally been legalized in the United States and some other nations. A hemp plant requires no fertilization and retains more water in the soil than other crops and has hundreds of beneficial uses including medicinal purposes.

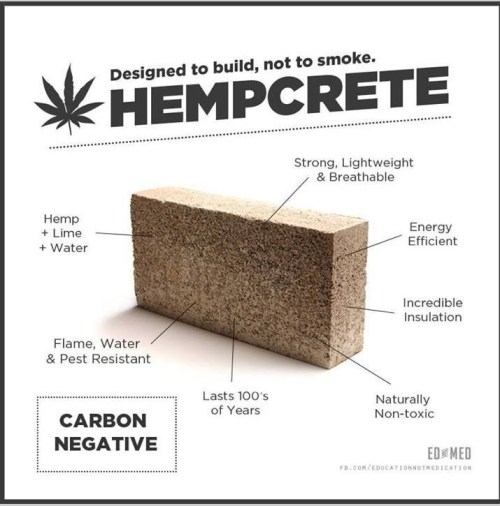

Besides all the important health and food benefits of hemp, hemp concrete or Hempcrete is carbon negative that sucks carbon out of the air. Builders emit more than a fifth of the greenhouse gas (GHG) emissions spewed into the Earth’s atmosphere every year and convincing them to adopt greener materials which include hemp and even straw will be key to keeping global temperature increases well below the 2 degrees Celsius (3.6 degrees Fahrenheit) mark mandated by the Paris climate accord. But it’s not just CLT’s potential to rapidly put the brakes on emissions that’s behind demand.

Therefore, across the globe greenhouse gas (GHG) emissions is a primary catalyst for climate change. Seeking out renewable energy investing options in sectors such as, water desalination and recycling will help stunt the acceleration of this global problem but may not repair the damage entirely especially in a rapid manner. To achieve the reversal of climate change effects, and return the planet to homeostasis, this requires a concentrated global effort on carbon sequestration.

A commonly known method for achieving carbon sequestration has been by planting trees. Carbon dioxide (CO2) is absorbed through photosynthesis which is converted into sugars required for energizing plants. Artificial alternatives are usually made up of specialized facilities or enhancements to existing power plants.

In recent years, this field of study has been progressing substantially, but still has obstacles to strive past to be a market ready option. However, the global implementation of carbon sequestration needs to have low technological requirements, be easily replicated, and financially profitable in order to sustain the initiative. Thus, only a few alternatives have been able to fulfill these requirements so progress in this field of study has been slow.

In a nutshell, hemp is a distinct tool in the war against climate change primarily for two fundamental reasons. The first reason is that growth and cultivation regarding the raw material which sequesters enormous amounts of carbon dioxide (CO2) is comparatively disproportionate to the size of an individual hemp plant. Secondly, the products derived from hemp continually sequestrate throughout their lifecycle. These can be commonly recognized in construction and plastics. The correct implementation and necessary support from governments and communities could propagate a hemp based economy that could harmonize both environmental activism and capitalism.

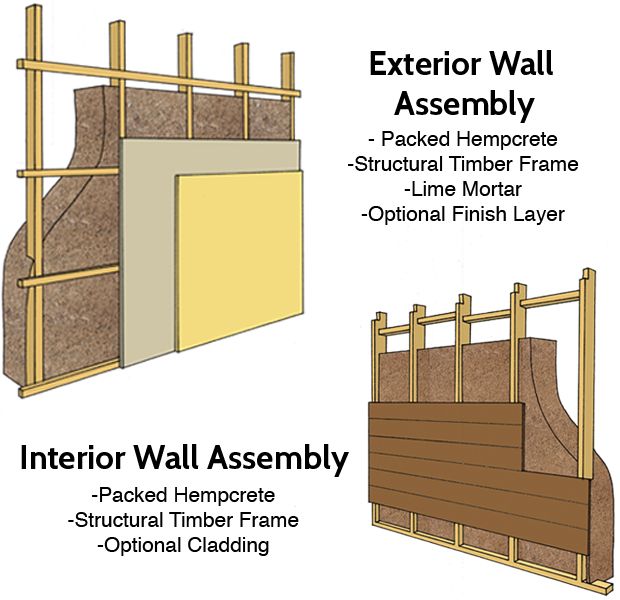

The use of hemp as a building material dates back to ancient times. The most famous hemp building is a hemp mortar bridge in France from the 6th century, and a lesser known fact is that the famous Colosseum had sunscreen awnings made from cotton, flax, and hemp. Hempcrete has been reinvented in France in the late 20th century, where new techniques for making hempcrete have been introduced.

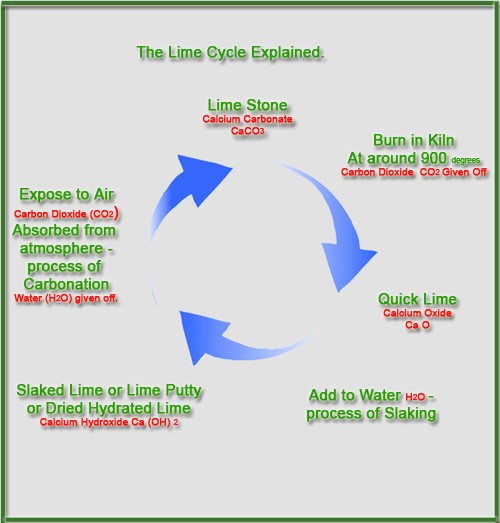

An organic building material called Hempcrete is derived from combining hemp hurd along with a lime based binder. This process in turn makes Hempcrete durable by being fire, water, and mold resistant as well as carbon negative. Homes produced from this building material serves as carbon sponges essentially transforming them also into passive air filters. Respectively, this is achieved by the process known as Carbonation. Furthermore, the Carbonation process is when a material absorbs carbon through absorbing the air continuously over extended periods of time, which becomes petrified in the hemp shiv. There is research indicating that per each ton of Hempcrete that is lime based it is projected to absorb and sequester approximately 249 kilograms (kg) of carbon dioxide (CO2) across a 100 year lifecycle.

The passing of the Agriculture Improvement Act of 2018 (2018 Farm Bill, Section 10113) removed hemp and hemp seeds from the Drug Enforcement Administration’s (DEA) schedule of Controlled Substances. This action removed hemp and hemp seeds from DEA authority for products containing THC levels not greater than 0.3 percent. Therefore, the DEA no longer has authority to require hemp seed permits for import purposes. U.S. producers and hemp seed exporters have requested assistance from USDA to provide an avenue for hemp seed exports to the United States. The U.S. Department of Agriculture (USDA) regulates the importation of all seeds for planting to ensure safe agricultural trade. Under this authority, the USDA is providing an alternative way for the safe importation of hemp seeds into the United States.

The classification of Industrial Hemp is categorized as a bast fiber crop that requires a hard wooden stem to be created to support itself. Consequently, this allows the plant to absorb an excessive amount of carbon dioxide (CO2) comparable to the plant’s size. There is research that indicates there are estimations which display that per each hectare of Industrial Hemp can in turn absorb 22 tons of carbon dioxide (CO2). Accordingly, this creates one of the quickest carbon dioxide (CO2) to biomass conversations which occurs in nature even more so than agroforestry. Rapid growth and tall height associated with hemp genotypes can be cultivated in an array of climates and in suitable regions can produce multiple harvests each season. The efficacy of hemp is increased from its ability to sequester carbon by diverting it into the soil through the process known as biosequestration.

Essentially, carbon dioxide (CO2) binds into the carbon sequestering material which permanently removes it from the atmosphere. However, Hempcrete is not by itself in this function. In accordance, to a study initiated by researchers from the University of Toronto, the utilization of hemp, natural fibers within thermoplastics have a high potential to serve as a sustainable “sink” for carbon dioxide (CO2) in the atmosphere and simultaneously saving non-renewable resources.